Pressure and Vacuum Calibration

What is pressure?

Pressure is force divided by area.

Several types of pressure: gauge, absolute, vacuum, differential and barometric. The main difference between them is the relative point.

What is Vacuum?

Vacuum is sub-pressure, which means pressure lower than atmospheric pressure

Calibrations in this field are performed without accreditation

Calibration Fields

- Calibrating analog pressure gauges

- digital

- barometric

- standard pressure gauges

- pressure calibrator

- physical parameters in autoclaves and complex machines

- Calibration of vacuum , calibration range 1.0E-07 torr at the customer site -vacuum generation by the customer

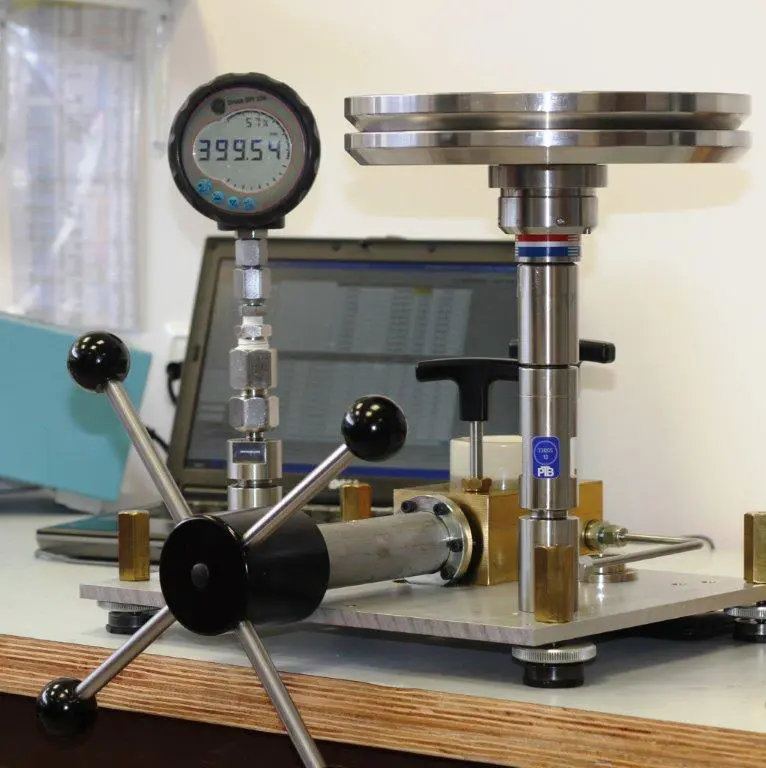

Calibration Method

Pressure pumps and high precision calibrators create pressure inside the tested instruments and the standard, results are compared.

Instruments may be calibrated using liquid (oil/water) or gas (air/nitrogen). For safety issues (having to avoid creating a spark in an oily gauge) and instrument’s cleanness, the two must not be mixed.

Pressure in medicine

In order to have a proper sterilization process the autoclave must reach specific temperatures (37°, 121°) and a specific pressure value.

Vacuuming air from within an autoclave leads to better heat transfer and to the temperature penetrating the packages and sterilizing the items.

An autoclave pressure gauge is calibrated to insure that pressure/vacuum values are as should be and that sterilization is preformed properly.

Pressure in the industry

Hydraulic systems are oil/water operated. Fluid pressure is what makes the system work.

Pressure gauges are to be calibrated periodically to maintain a safe procedure for both the organization and the employees.

Differential pressure gauges are installed inside and outside of clean room. Fragments that may damage the procedure in the clean room are vacuumed out of the space thanks to different pressure values inside compares to outside. Pressure calibration may perform on site or in house.

Pressure in aviation and diving

The air force, EL-AL and other airline companies, parachutists, and submarines use pressure gauges and high/depth gauges. Rising to water level or skydiving too fast may have a lethal effect on the human body and the compartment under inner or outer pressure. Pressure gauges convert atmospheric pressure to height (in meters). Pressure values change depends on the distance from earth core and provides the pilot/parachutist the crucial information which could get him back home safe and sound.

Vacuum calibration in the industry

Vacuum transducers are used for dry freezing. Deep vacuum droppes the temperature to an extreme low. In these conditions materials are dried and concentrated

In the industry, vacuum ovens prevents oxidation and seals metals.

To view the scope of pressure accreditation click here

Phone call

Phone call